The story behind Interspiro

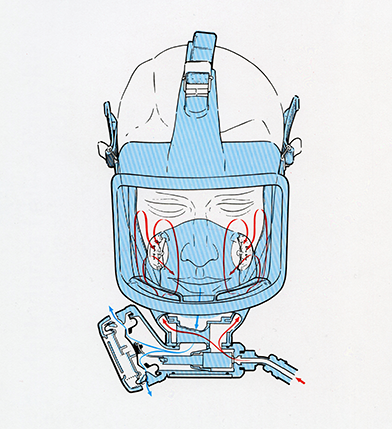

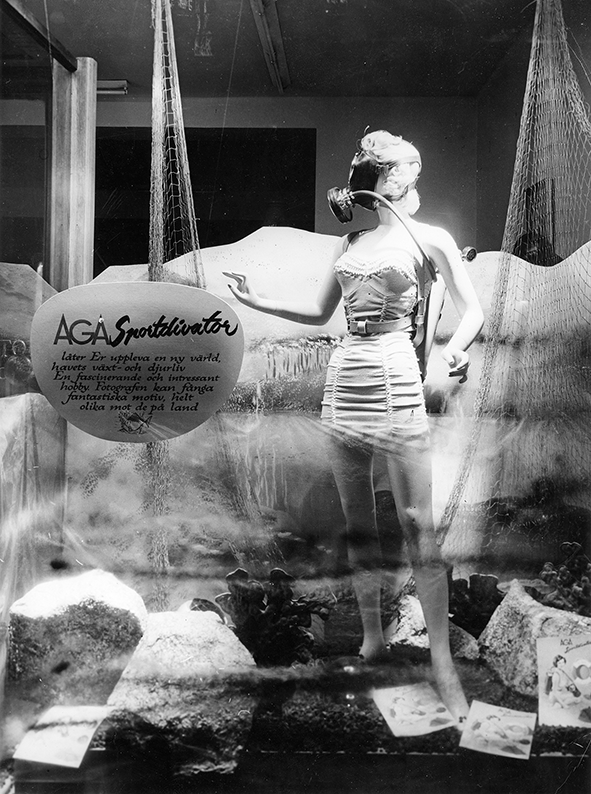

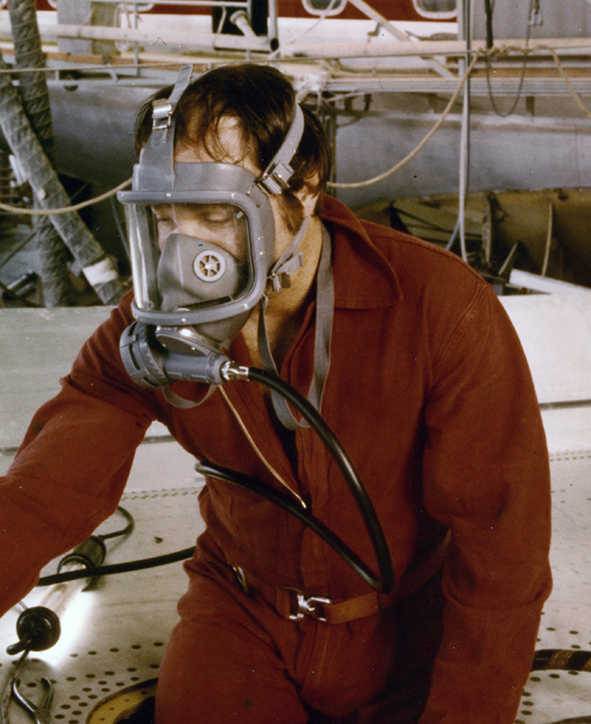

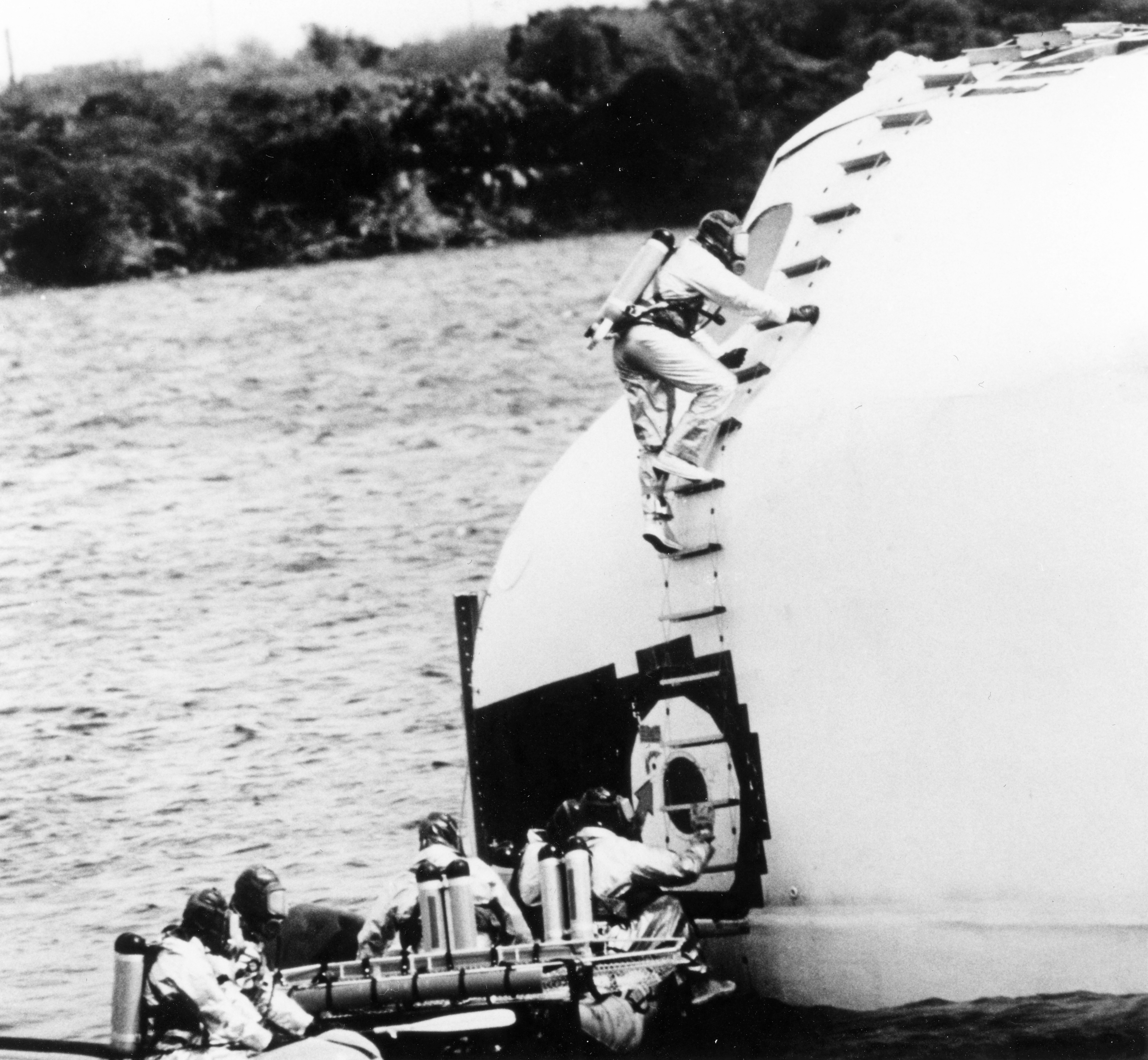

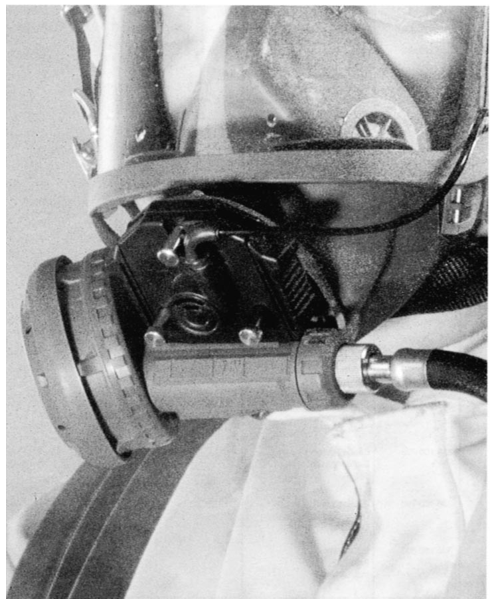

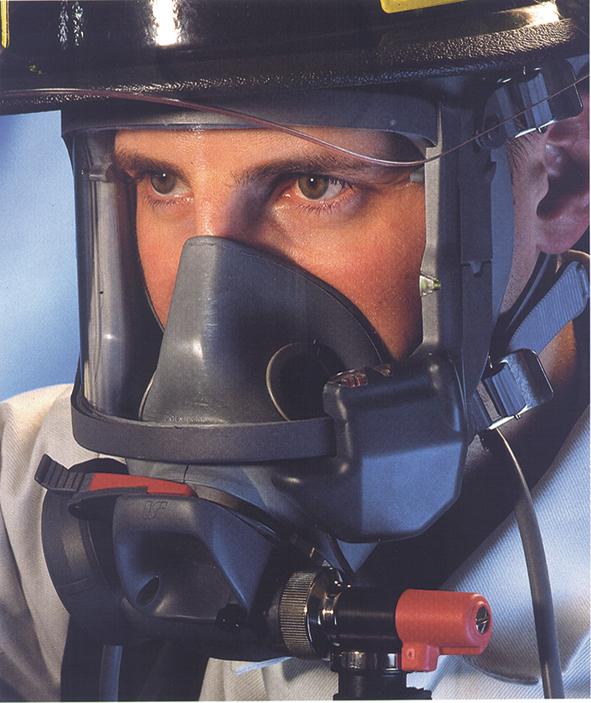

Since the 1920’s we have developed respiratory protection for non-breathable environments above and below ground. Our technological milestones have been numerous and many of them have become industry standard. Since 2003 we have been part of the Ocenco group, one of the world leaders in respiratory protection.

eLearning

eLearning